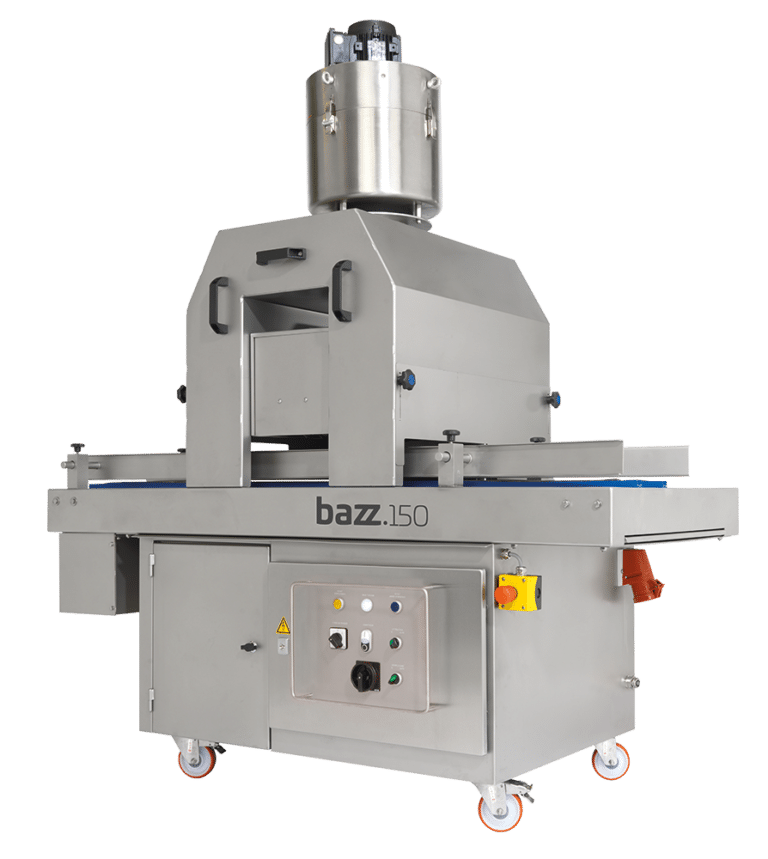

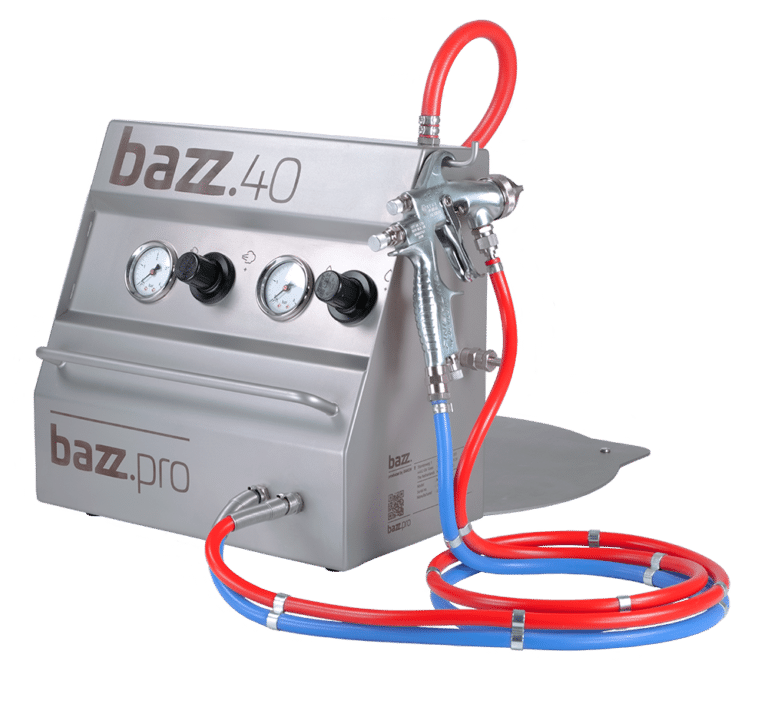

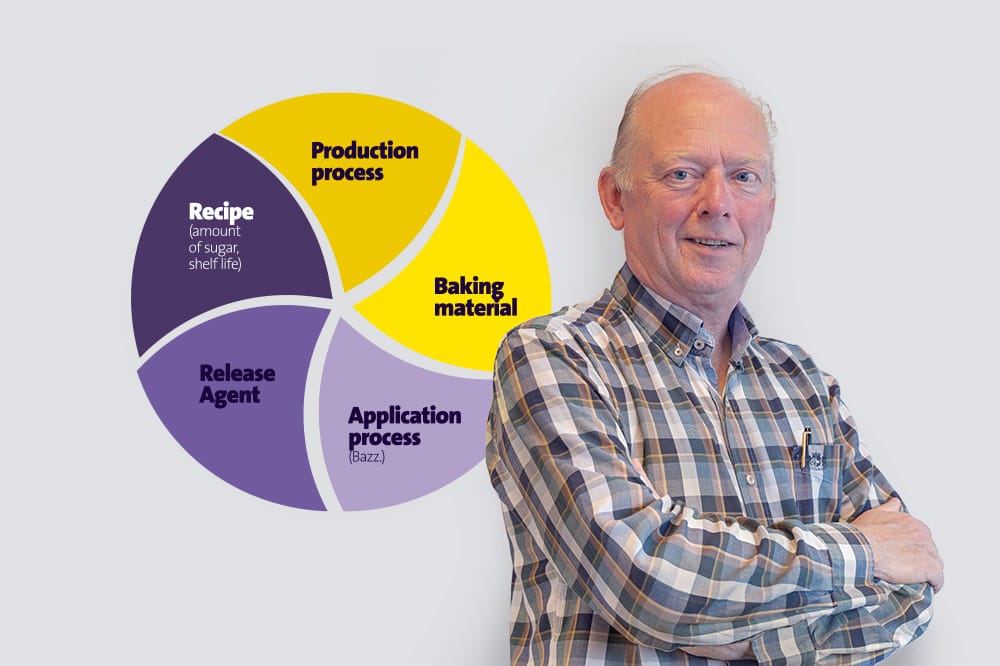

Looking for a reliable solution to ensure smooth product release in your bakery? bazz depanning oils are designed to help industrial bakeries achieve flawless results. As a collaboration between BAKON and Zeelandia, bazz offers depanning oils that guarantee your baked goods release easily from molds and trays, maintaining their shape and quality without sticking.

Whether you’re working with sticky, sugar-heavy recipes or delicate pastries, our high-performance depanning oils—like CARLEX® and CARLO®—are formulated to meet your specific needs. These oils ensure smooth production processes, reduce waste, and deliver consistent results. With bazz, you can optimize your bakery's efficiency while enhancing the quality of your products, batch after batch.